Technology Trends

Radio Frequency Identification (RFID) is a popular choice for electronic identification and RFID positioning technology. RFID offers substantial advantages for businesses allowing automatic inventory and tracking of the supply chain. This technology plays a key role in pervasive networks and services. Storage and remote retrieval of data on RFID tags enable real-time identification of devices and users. However, identification information, if linked to location, could optimize the usage of RFID.

RFID positioning technology is transforming industries by enabling real-time locating RFID solutions for inventory management, security and personnel tracking. From RFID indoor tracking in warehouses to RFID tags for location tracking in healthcare and logistics, businesses are leveraging this technology to enhance efficiency.

The venerable RFID tag traces its origin to the “friend or foe” transponder systems developed for military aircraft beginning in WWII. Since then, RFID has earned and retained its status as a reliable asset-tracking system.

In recent times, RFID positioning technology has been a default choice for several real-time indoor tracking of people. In this article, we’ll explore how RFID location tracking works, how it enables indoor asset tracking (people monitoring) and how it compares to alternative solutions.

How Does an RFID Tracking System Work?

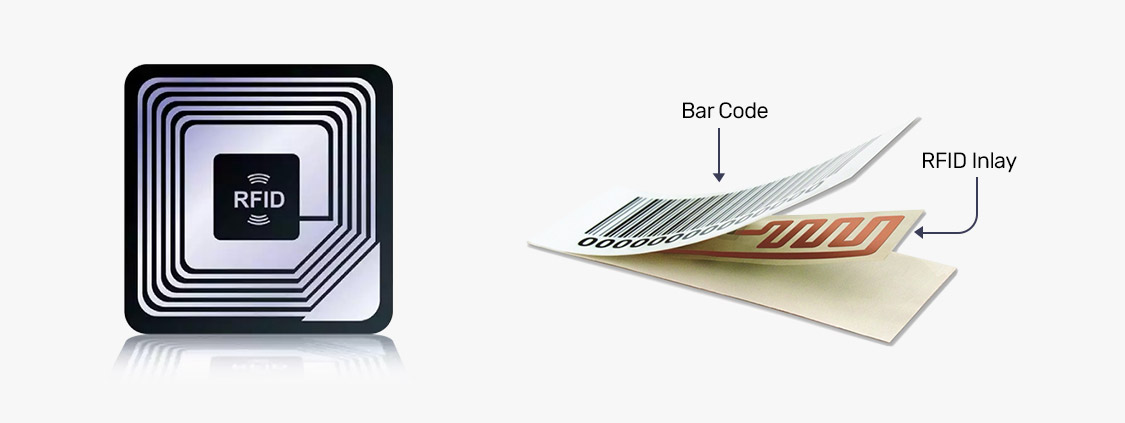

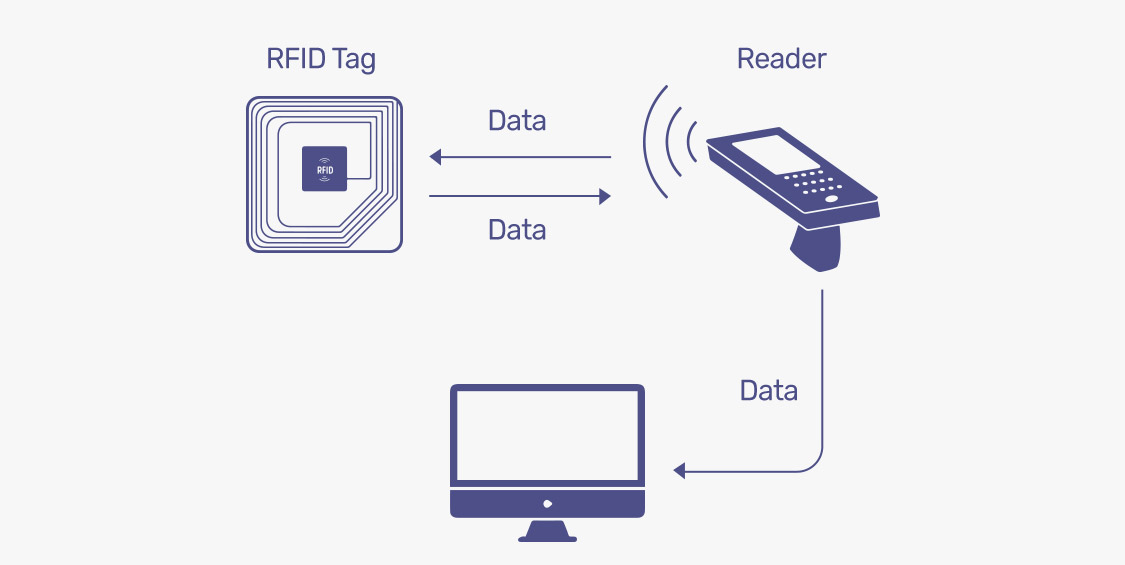

An RFID tracking system comprises three different entities – RFID tags, readers and servers. All RFID tags use radio frequency energy to communicate with the readers. However, the method of powering the tags varies. An active tag embeds an internal battery that continuously powers it and its RF communication circuitry. Readers can thus transmit very low-level signals and the tag can reply with high-level signals. An active tag can also have additional functionalities such as memory, a sensor or a cryptography module.

On the other hand, a passive tag has no internal power supply. generally speaking, it backscatters the carrier signal received from a reader. Passive tags have a smaller size and are cheaper than active tags, but have very limited functionalities. The last type of RFID tag is a semi-passive tag. These tags communicated with the readers like passive tags, but they embed an internal battery that constantly powers their internal circuitry.

RFID position-tracking readers have two interfaces. The first one is an RF interface that communicates with the tags in their read range in order to retrieve the tags’ identities. The second one is a communication interface, generally IEEE 802.11 or 802.3, for communicating with the servers.

Finally, one or several servers constitute the third part of an RFID system. They collect tags’ identities sent by the reader and perform calculations such as applying a localization method. They also embed the major part of the middleware system, allowing each layer to the couple.

The specific means by which the RFID tags and readers communicate (i.e. their coupling mechanism) determines the range, complexity and cost of the specific system. (“Coupling” in this context refers to an energy transfer between tag and reader). Currently, three types of coupling mechanisms compete in the market: inductive, capacitive and backscatter.

The use of RFID tracking devices in industrial and commercial spaces allows for seamless monitoring of assets, reducing manual intervention and increasing accuracy. Understanding how RFID tracking works is essential for businesses considering its implementation.

Using RFID Location Tracking to Track Assets

Unlike traditional tracking solutions, RFID positioning technology offers hands-free, real-time tracking, making it ideal for high-security environments. Industries such as manufacturing, healthcare and retail are integrating RFID indoor tracking to streamline operations and improve visibility across supply chains.

Inductive Coupling

The inductive coupling has been present since the early days of RFID when the systems involved bulky tags with complicated antenna mechanisms used to track large objects (e.g. cars or cattle). An inductively coupled tag draws energy from the magnetic field created by the reader and modulates it. The reader then measures the perturbation produced by the tag and decodes it as data. The magnetic fields used in these RFID localization systems drop off rapidly, affording inductive coupling an RFID tracking range of about 1cm to 1m.

Capacitive Coupling Systems

The creation of Capacitive Coupling systems shrunk the cost and size of RFID when large inductive systems were the only RFID positioning option on the market. They employ conductive patches on both the reader and tag to form a capacitor and signal data by varying the capacitance of the circuit. These systems are extremely close range –1cm– and require orientation of patches matters. A typical application is an ID card with an embedded RFID chip.

As inductive circuits shrank, so too did the market for the more limited capacitive systems. Indeed, most RFID indoor tracking and positioning systems today use some version of inductive coupling. However, the magnetic fields’ rapid drop in strength at a distance is still a hindrance. To achieve a longer range reliably, RFID positioning systems must use higher frequency signals and rely on the electric side of the electromagnetic signal.

Backscatter Coupling

Backscatter coupling employs a reader that sends out a UHF or microwave signal that impinges on a tag and then reads patterns in the reflected energy. Whether the increased range is an advantage or disadvantage depends, of course, on the use case. Scanning pallets as they pass through a large warehouse gate? Great. Unlocking doors or disseminating payment information? Probably less desirable.

Using RFID Location Tracking to Track Assets

Before assessing RFID positioning’s merits as an indoor asset tracking technology, we need a clearer definition for the term “tracking”. RFID positioning has, since its inception, performed asset tracking in a sort of spreadsheet sense. It makes it simple to identify and log which tracked items are nearby. If your goal is to make sure all the train cars that went through gate A also made it through gate B or whether an employee swiped into a building, then RFID indoor positioning is a well-tested and proven solution.

In such use cases, RFID competes most directly with barcodes or QR codes. It offers the obvious advantage of being readable at a distance. Active or semi-active RFID positioning tags can provide valuable sensor information. On the other hand, passive readers are very expensive and powered tags are costly and have a limited lifespan.

A more challenging type of tracking is knowing the (nearly) real-time location of a tracked asset. Although this is a relatively recent use case for RFID localization, there are already quite a few commercially available solutions on the market.

The way these systems work varies. Some systems use RFID positioning purely for object identification while leveraging another technology for ranging. Those that rely purely on RFID almost exclusively use active RFID tags. There’s some exciting research that uses passive RFID tags, but the cost of passive readers and the low range of these systems makes them commercially prohibitive.

Real-time location systems (RTLS) that use active RFID positioning tags behave similarly to competing technologies- Bluetooth, Bluetooth Low Energy (BLE), WiFi, Ultrasonic and Ultra-Wideband (UWB). The RFID location tracking versions are largely based on the LANDMARC system, which determines location by comparing the Received Signal Strength (RSS) of an active tag’s signals with the RSS of reference tags with a known location.

Active RFID position tracking has a much greater range than BLE. It’s capable of spanning a kilometer in the open air. Compare that to BLE’s ~70m. This is less important in indoor environments with obstructions (e.g. walls or floors), but in warehouses or barns, active RFID’s range might allow businesses to make do with fewer readers, cutting costs and reducing potential failure points.

RFID Positioning Tag Selection Considerations

In spite of the numerous RFID positioning tag and inlay options available today, tagging items remains one of the most significant challenges to implementing a successful RFID system, Before engaging in the effort to tag your items, you should take some time to consider the workflow and business processes associated with the items you wish to tag.

For example, if you are tagging a medical instrument, at some point in the workflow it may go into an autoclave. It is important that the tag can survive the autoclave process. Another example is a tool on a bench that may have many areas where a tag is easier to attach and read. However, for equipment maintenance using the tool, there may be not enough clearance with the addition of the tag.

Understanding the lifecycle of the items(s) will ensure that the selected RFID positioning tag will enhance, rather than interfere with those processes. Additionally, taking into consideration the five factors of tag selection will further ensure a successful system deployment: Read Range, Environment, Application, data requirements and size.

Read Range

Read range is simply the physical distance between the tagged assets and an RFID tracking system, each RFID tag or inlay has a specified read distance when used in its optimized environment. Today, Passive RFID positioning tags vary in read range from just a few inches up to a hundred feet.

Fixed readers or handheld readers are ideal for tag reading. The former is most likely a permanent installation in a channel, readily detecting tags moving into its red zone.

Handheld readers enhance operational flexibility by allowing a user to bring the device to the point of work or the tagged items, rather than moving tagged items past a fixed reader. As a general rule, fixed readers will have a 25% greater read distance than handheld devices.

Environment

The environment in which your tagged asset will live is very important. If it will primarily be housed outdoors or exposed to moisture, chemicals and low or high temperatures, then the encasement of a tag or the label material and adhesive will play a big factor in selection.

A passive RFID tracking system tag’s performance can be significantly decreased if there is metal or liquid in the surrounding environment, as both substances interfere with RF signals operating in the 860-960 MHz band-water absorbs the radio waves while metal reflects them.

Today it’s easier to find specialty tags that perform in RF-unfriendly environments. Likewise, it’s easier to customize label materials and adhesives to survive in these harsher environments.

Application

Application refers to the actual material makeup of items that will need tagging or the surface to attach the tag. Here, identifying where to attach is equally important as choosing the right method to do it

Surfaces such as plastic are considered to be RF-friendly surfaces, so a standard pressure-sensitive RFID tracking system should work well when tagging these types of products. One exception is when the item being tagged contains liquids. There are some inlays that perform better than others in the presence of liquids. Just as the presence of metal and water in RFID positioning systems’ surrounding environment may pose challenges, so will the actual tagging of those types of items. In these instances, tags that have been specially constructed to minimize the RF interference of these substances must be chosen.

Data Requirements

When selecting an RFID tag, data requirements are another important consideration. You will need to consider the amount of data that needs to be encoded in the chip as well as any other requirements, such as having the data human-readable or including a barcode. This may dictate the type of tag and the encoding/imprinting method.

Size

The size of the tag you select is dictated by the size of the asset being tagged and is dependent on the space available to place the RFID tag. On many assets such as shipping containers and vehicles, there is plenty of available space to successfully affix a tag, but available real estate on smaller assets can be very limited. A tag must not be placed in an area that could potentially compromise a product’s functional purpose.

Over the last several years, RFID positioning tags and inlay manufacturers have responded to the need to tag very small, high-value assets such as prescription drug bottles, tools and electronic equipment where available space to place the tag is limited. As a result, there are many tag options now available on the market, but it is important to remember: the smaller the tag, the shorter the read distance.

Frequently Asked Questions

Q1. What is meant by RFID?

Ans. RFID is the abbreviation for Radio Frequency Identification.

Q2. What are the two types of RFID tags?

Ans. There are two types of RFID tags. Passive and active. Passive tags use no internal power source and are powered by an RFID reader. They are commonly used for file and supply chain management. Active tags are battery-powered and continuously broadcast their position. They are useful in asset tracking and tolling stations.

Q3. How does a passive RFID tag work?

Ans. A passive RFID tag has two components. The tag itself and the reader. The passive tag contains a circuit of data and an antenna that transmits and receives signals. The reader has a transceiver that transmits an encoded signal which alerts the tag. The tag is powered by the signal and can then send back a relative position to the reader.

Q4. How does an active RFID tag work?

Ans. An active RFID tag works in a similar way except it has a battery. This battery extends the signal much further than a passive tag because it has an internal power source. This means that active tags can be much further from an RFID reader without losing signal strength. This makes them ideal for asset tracking in a large warehouse for example.

Q5. What are the benefits of RFID tags?

Ans. Passive tags can help with data collection and eliminate a time-consuming process. They also require little to no maintenance because they do not have a power source. Active tags can help you keep track of items and inventory as well as countless other things. So many processes can be optimized with RFID as they allow for determining the location and controlling material flow.

Q6. What is RFID positioning technology?

Ans. RFID positioning technology uses radio frequency signals to track and locate objects, assets or individuals in real time. It enables RFID indoor tracking for industries such as healthcare, logistics and retail.

Q7. How does RFID tracking work?

Ans. RFID tracking works by using tags, readers and a central system. The RFID tracking devices communicate wirelessly, allowing businesses to monitor assets efficiently and accurately.

Q8. What are the advantages of real-time locating RFID solutions?

Ans. Real-time RFID tracking offers precise location data, reduces manual errors, enhances security and optimizes inventory management. It is widely used for RFID indoor tracking and supply chain visibility.

Q9. What are the different types of RFID tags for location tracking?

Ans. There are three main types of RFID tags for location tracking:

- Active RFID tags: Have an internal battery for long-range tracking.

- Passive RFID tags: Rely on external signals, making them cost-effective.

- Semi-passive RFID tags: Combine both features, offering improved functionality.

Q10. Can RFID technology be used for indoor tracking?

Ans. Yes, RFID indoor tracking is commonly used in smart buildings, hospitals and warehouses to monitor assets and personnel in real time.

Q11. How does RFID compare to GPS tracking?

Ans. RFID is more suitable for short-range tracking in enclosed environments, while GPS provides location data for outdoor navigation. RFID positioning technology is preferred for inventory and asset management.

Q12. What industries benefit the most from RFID positioning?

Ans. Industries such as logistics, healthcare, retail and manufacturing leverage RFID technology to enhance operational efficiency, security and automation.