IoT Solutions

Warehouse operations face increasing pressure to become more efficient and effective as e-commerce and global supply chains continue to rise. IoT has aided this transformation by streamlining processes, providing real-time data, reducing costs and improving overall efficiency. The global IoT market is estimated to exceed $1.1 trillion in the coming years, with warehouses set to benefit significantly.

Smart warehouses are embracing future-focused IoT technologies. These devices enable warehouses to optimize asset tracking and personnel monitoring to enhance overall safety, making them crucial in today’s fast-paced logistics industry.

Read on to learn more about the role of IoT in warehousing. We’ll cover how it works, what solutions are available and how warehouses can embrace a smarter future.

Overview

Did you know that more than seven-in-10 companies intend to automate their warehouses with IoT in the next five years? This staggering statistic highlights the critical role of IoT in warehouse management. These changes will create fully automated, intelligent storage systems capable of achieving unparalleled operational efficiency and accuracy. Solutions like Mapsted’s innovative suite of IoT devices, with their minimal hardware requirements, simplify asset tracking, help reduce operational costs and boost productivity.

The Role of IoT in Warehousing

By improving visibility, reducing errors and enabling data-driven decision-making, IoT can be highly beneficial to warehouse operations. The role of IoT in warehousing extends across several areas.

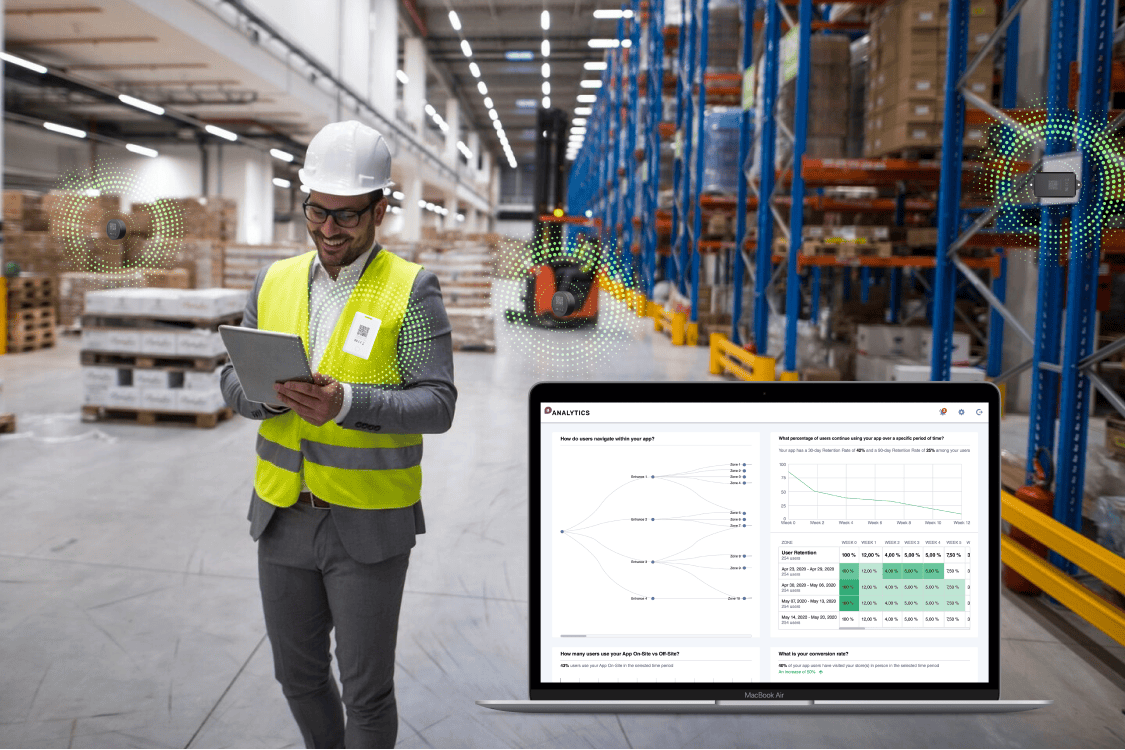

- Real-Time Equipment Management: IoT-enabled sensors and tags help to continuously track valuable equipment data accuracy at all times. Mapsted’s Tag analytics dashboard, for example, provides real-time insights for efficient management, asset tracking and quick decision-making to maintain accurate data.

- Automation and Robotics: IoT supports and works alongside automation technologies, like Automated Guided Vehicles (AGVs) and robotic systems. It enables smooth operations by reducing the need for manual interventions. Mapsted’s asset-tracking solutions integrate easily with these systems and guarantee real-time updates and location monitoring.

- Predictive Maintenance: Environment conditions in warehouses such as temperature, humidity and other relevant parameters are tracked by IoT-based sensors. This ensures a reduction in downtime by enabling proactive repairs.

- Environmental Monitoring: IoT sensors monitor temperature, humidity and other environmental factors in warehouses. This helps to make sure that there are optimal storage conditions for sensitive goods.

- Enhanced Security: IoT-based security systems safeguard assets by monitoring activity and sending real-time alerts for any security breaches. Mapsted’s Badge personnel monitoring system also assists in personnel tracking for added security and accountability.

How IoT Optimizes Warehousing

IoT supports warehouse functions by implementing a design of interlinked devices that monitor real-time data for analysis and necessary actions. Here are some of the ways IoT can enhance warehouse performance:

- Data-Driven Decision Making: IoT devices collect vast amounts of data, which can be analyzed to optimize inventory management, predict future demand and improve supply chain efficiency. Mapsted’s Flow solution offers real-time heat mapping, allowing warehouse managers to visualize traffic and make better logistical decisions.

- Minimized Human Error: By automating data collection and processing, IoT eliminates errors commonly associated with manual entry and inventory tracking. Mapsted’s compact tags reduce the need for manual entry and minimize errors by providing real-time, accurate data.

- Improved Order Fulfillment: With IoT-powered systems, warehouses can achieve faster order processing and reduced picking errors, leading to higher customer satisfaction. Mapsted’s real-time heat mapping and Badge personnel monitoring help streamline workflows by improving space utilization and optimizing staff allocation, contributing to smoother operations.

Cutting-Edge IoT Solutions in Warehouse Management

The integration of IoT solutions in warehouse management has led to significant advancements in logistics and operational efficiency. Here are some of the most common IoT solutions used in warehouses today:

- Smart Shelving Systems: These systems use IoT sensors to monitor stock levels and send automated alerts when inventory is low, ensuring timely restocking.

- Automated Picking and Packing: IoT sensors integrated with robotic systems streamline the picking and packing process, reducing labour costs and speeding up order fulfillment.

- Telematics and GPS: IoT-enabled vehicles can be tracked in real-time, providing accurate delivery schedules and reducing delays in the supply chain.

- Wearables for Personnel: IoT wearables track the performance and location of workers, ensuring safety and optimizing task allocation based on real-time data. Mapsted Badge devices, available in clip and wristband forms, offer robust personnel tracking solutions, enhancing management with features like long battery life and emergency SOS buttons in warehouse environments.

- Energy and Resource Optimization: Smart lighting and climate control systems, powered by IoT, reduce energy consumption by making adjustments as per warehouse conditions.

How to Choose the Right IoT Platform and Technologies for Your Warehouse

When it comes to selecting the ideal IoT platform for your warehouse, it often proves to be challenging due to the wide range of available solutions. In order to ensure successful implementation, focus on the following key factors:

- Scalability: Make sure that the platform can expand with your business as well as its future needs.

- Integration: Make sure that the chosen solution fits well within the organizational existing processes and systems.

- Security: Include robust security measures to protect sensitive data, including authentication protocols and encryption.

- Cost Efficiency: Balance initial investments with long-term operational costs by evaluating the total cost of ownership.

- Network Infrastructure: Select a reliable network, using both wired and wireless (controllers supporting authentication and encryption) configuration to support IoT endpoints.

The selected solution should seamlessly integrate with your existing systems as well as provide robust security protocols and the necessary equipment like RFID tags, sensors and wearables. Continued assessment and maintenance are needed to sustain the benefits of IoT in your warehouse.

The Future of IoT in Warehousing

The outlook is quite promising as far as the future of IoT in warehousing is concerned. With ongoing advancements in the Internet of Things (IoT), the efficiency and flexibility of warehouses will be enhanced further. The expansion of 5G technology will also be advantageous to warehouses for faster data transmission, making real-time monitoring and automation more effective. Mapsted’s innovative IoT solutions, like heat mapping, are expected to optimize warehouse layouts and improve overall operational efficiencies.

Conclusion

Traditional warehouse management processes include numerous time-consuming tasks that need to be done manually. But today the IoT in warehouse management has not only automated a majority of these processes but also streamlined operations, reducing costs and making it more efficient. The role of IoT in warehousing will only grow in the future as it is capable of meeting the demands of the modern supply chain. Mapsted’s IoT solutions, with their minimal hardware requirements and robust analytics platforms, offer practical tools for warehouses to tackle the challenges faced by warehouses.

If you found this blog helpful, don’t miss our blog post on What Is Heat Mapping and How Can It Help Your Business? or watch our video on Unlock the Potential of Location Technology with Mapsted to learn more.

Frequently Asked Questions

Q1. What is IoT and what are its applications in warehousing?

Ans. IoT technology requires internet connectivity to connect smart devices like sensors that collect and share data in real-time. IoT devices can easily track, monitor and manage inventory conditions and various processes.

Q2. What are the commonly used IoT solutions in warehouses?

Ans. Some of the common IoT solutions are smart shelving, automated picking systems, GPS vehicle tracking, personnel wearables and sensors for environmental monitoring. These systems boost efficiency and safety.

Q3. How do Mapsted’s IoT solutions help in warehouse management?

Ans. Mapsted’s IoT solutions address the issues of real-time asset tracking, space utilization and personnel monitoring. They optimize warehouse operations with minimal hardware and advanced analytics.

Q4. What are some of the successful examples of IoT in warehouse management?

Ans. Amazon, DHL and Walmart are some of the big brands transforming their warehouse management with IoT. For example, Amazon utilizes smart bots for automating material handling. DHL uses smart sensors for real-time tracking and inventory management, while Walmart has implemented self-driving forklifts to reduce manual manoeuvring.